Rip Saw Instruction Procedure

Purpose

To make a straight edge on an unfinished board for a more consistent cut.

Power on Machine

|

1. Press the green button to start the saw blade |

|

|

2. Press the green button to start link chain conveyor Chain conveyor will not start if the saw blade is not running |

|

|

3. Open gate to the dust collector |

|

Machine Set Up

|

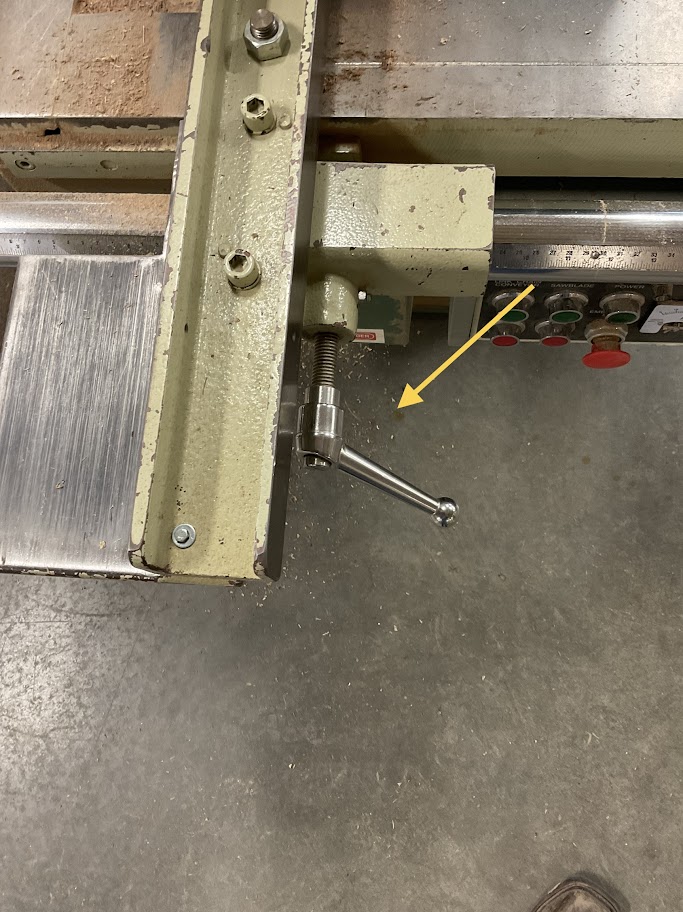

1. Start by loosening the clamp to set conveyor height |

|

|

2. Turn the wheel to adjust the conveyor height then set the clamp back into the locked position Height should be set to 1/8 less than the thickness of the board to be cut |

|

|

3. Turn on laser guide |

|

Explain to the employee why the conveyor height needs to be set 1/8 of and inch less than the boards thickness

Ripping Part

|

1. Set the front right side of the board in the center groove of the conveyor |

|

|

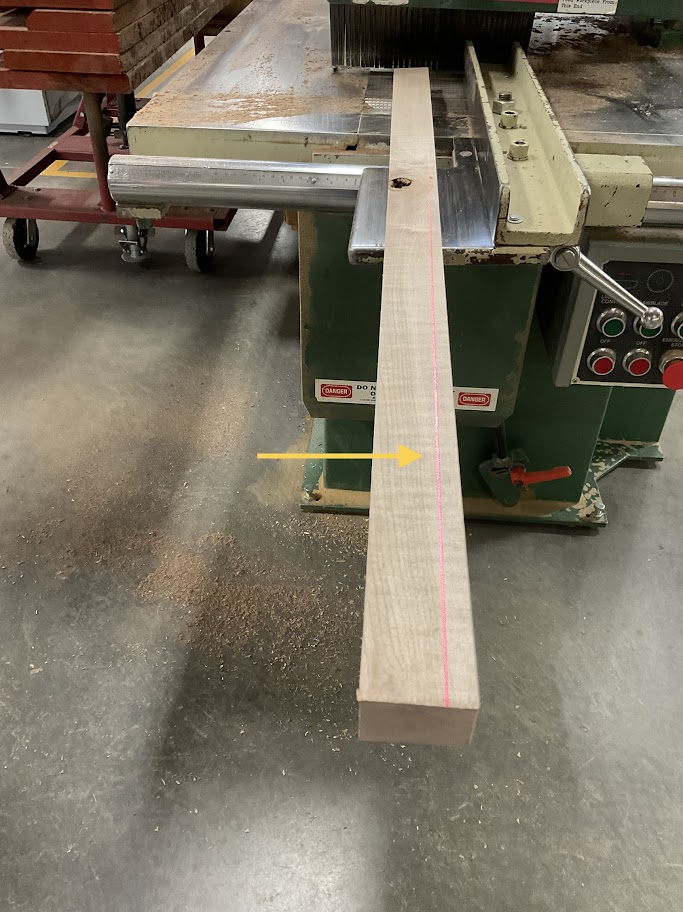

2. Line up the back of the board with the laser guide |

|

|

3. Push the board forward till the conveyor catches it If the conveyor doesn't grip the board, stop the machine and double check your conveyor height |

|

4. After the board passes through the rip saw, verify that you have a smooth straight side.

|

5. Loosen the fence clamp |

|

|

6. Set fence to measurement the board needs to be and set the clamp back into the locked position |

|

|

7. Set the smooth side of the board flat against the fence and push the board back through the conveyor |

|